Build log for the Tigerhawks M134 minigun.

If you’re looking at building one of these I highly recommend looking through the content available out at DIY M134 Minigun Tutorials

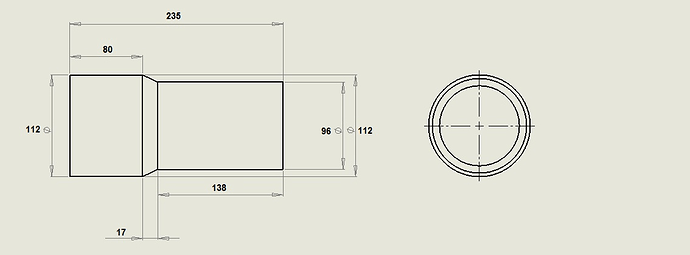

My goal for this build is to create a prop M134 that closely matches the design and look of it. It is not accurate to the mm on dimensions but it’s close enough.

I started with the body of the minigun and worked forwards to the muzzle.

Body

Built from various PVC fittings, the 112 mm diameter portion is a chunk of 4" schedule 40 PVC (which has an OD of 114 mm.

Barrels

The most iconic part of the minigun in my book! So it was really important to me to nail the look and feel here. The barrel assembly is made up of 6 barrels, 5 barrel clamps plus some odds & ends.

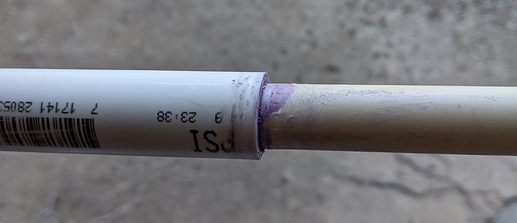

The barrels were constructed from two lengths of 1/2" pipe, smaller diameter is CPVC schedule 11 and the larger diameter is PVC schedule 40. PVC Cement and a rubber mallet were used to persuade the smaller pipe to fit into the larger one.

The barrel clamps were modeled in Fusion 360, and I used a laser cutting service to do the hard part.

The clamps were cut out of 1/4" black acrylic. For the middle and base clamps several 1/4" pieces were joined together. (Happy to share the drawings if anyone wants them)

The first 3 clamps and the five pieces for middle clamp were affixed to a center shaft. Then each barrel was fitted to the clamp, alignment checked and glue in place. Then I repeated the process for the 5 pieces that made up the base clamp.

Finally here are a few shots of the barrel assembly and the body together.

More coming soon!